What is TIG Welding?

Is your exhaust system from TIG welding?

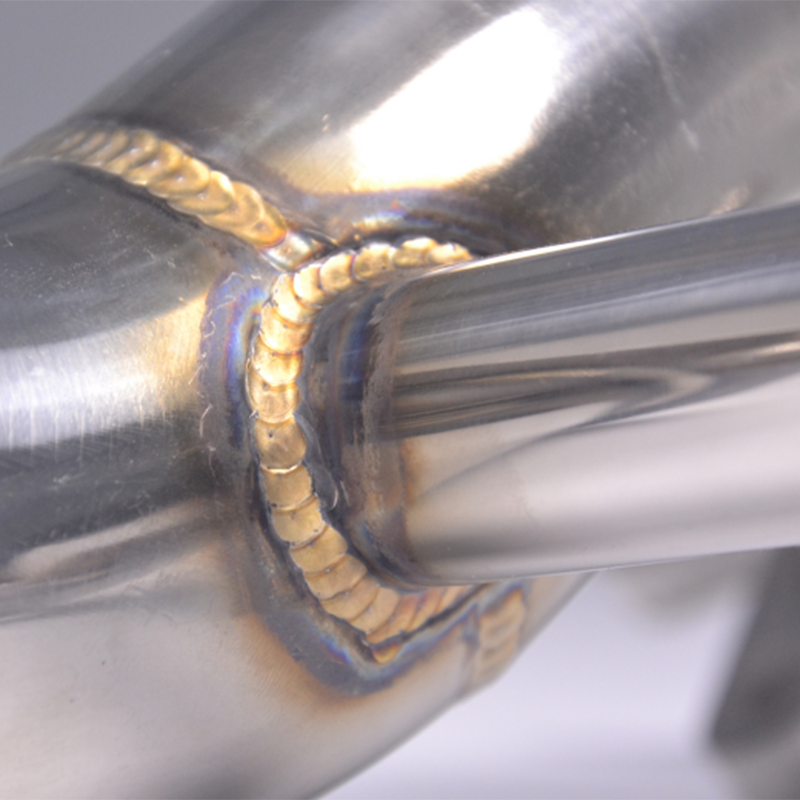

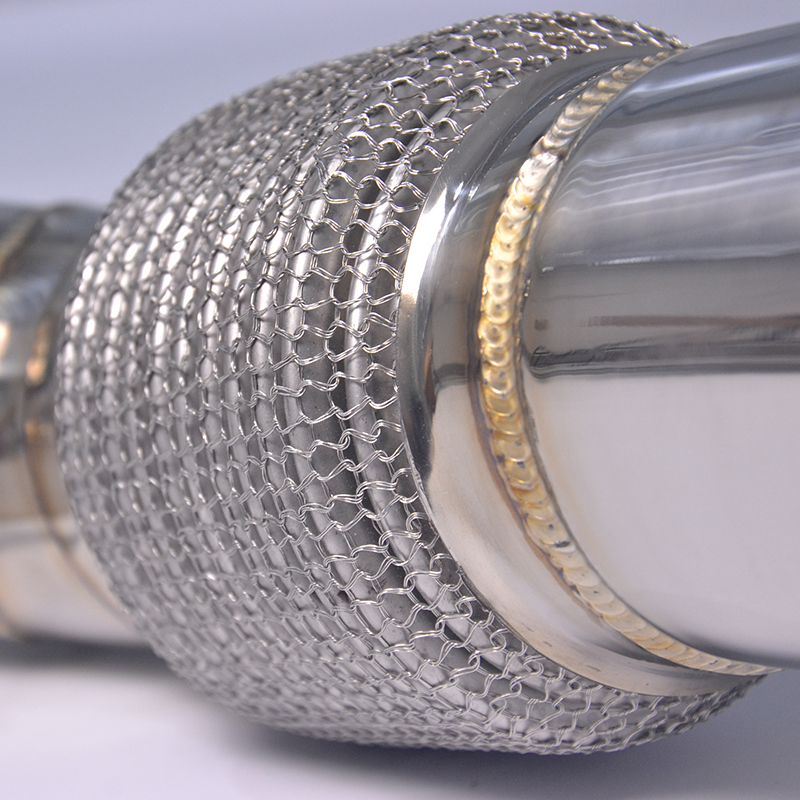

TIG welding is also called fish scale welding,which is a highly versatile process that can be used on thin sheets of metal. It also works very well with alloys such as stainless steel and aluminum.It is called fish scale welding because of the welding planelooks like fishscale.

Welding method: The most important thing is to select the welding point, power, knock out the arc with the welding rod head, so that the flux in the welding rod is melted, and then the left and right small amplitude swing the welding pliers, so that the welding core is evenly melted in the welding position, which is characterized by direct welding of pipes to pipes, just like catback.

How does it work?

First, at the beginning of TIG welding, the filler line is added after heating the metal rod with a welding torch and bringing it close to the material to be connected and make them are heated. Metal rods are then combined with these materials to form a strong bond that holds everything together.

Secondly, the use of argon or carbon dioxide gas as an alternative to air provides more protection for TIG welding.

Finally, TIG welding requires a steady hand and good coordination, especially when working with more complex parts or using very thin parts. It also usually takes more time than other types of welding.

Advantages of TIG welding:

First, it uses an arc to produce less splash than some other methods, which allows for better control when dealing with thin metal sheets. While you’re still in the process of welding, these parts tend to cool faster.

Second, it produces few waste by-products or particles, which reduces environmental pollution or poses a safety hazard.

Disadvantages of TIG welding:

First: the difficulty of use and high cost. First of all, using TIG welding requires the hand and arm movements of the welder to be very dexterous, and many beginners find even basic welding difficult. Second, it requires the use of specialized equipment and filling lines, so this makes TIG welding more expensive than some other types of welding.

How does it compare with other types of welding?

TIG welding is considered a “high-end” form of welding because in addition to requiring the welder to have very precise control over the finished product, it also requires the welder to have a better understanding of the material and which metal is used to fill the line in order to achieve the desired strength of the finished product. In contrast, MIG welding is more rough, and may look a little messy, so the cost of TIG welding is relatively expensive, Our products are often welded with this method, such as Downpipe. The more important point,about this kind of products, we not only accept the customization of welding methods, but also provide two colors blue and yellow for you to choose.

Precautions for using TIG welding:

First, make sure your workspace has adequate ventilation so that oxygen levels are low when you’re working. This will help reduce contaminants and fumes from heating the metal during the welding process.

Secondly, make sure that the floor under the welding is non-flammable, as sparks or hot metal can pose a fire hazard. For the same reason, be careful not to perform TIG welding near exposed gas or fuel lines or flammable objects.

Finally, wear protective clothing while welding. This includes long sleeves, thick pants, leather shoes that cover the ankle, and hand protection in the form of gloves or welding gloves made of flame retardant materials.

Plus, welding helmets are another important item because they protect your eyes from flying glass.

Post time: Nov-23-2023