Now, Let us talk about the design of exhaust systems for a second.

So when a manufacturer designs an exhaust system, there is some constraints on that design. One of those constraints is fitment. So the exhaust header, particularly, needs to fit and be packaged into an engine bay, it need to route around various obstacles and make its way to the rear of the vehicle. So fitment is a key constraint.

Another constraint is noise. So the exhaust system needs to achieve a certain level of noise reduction. A third element is cost, so the manufacturer needs to build an exhaust system at a certain cost of manufacturing and fitting that system. We also have emissions, so the exhaust system needs to achieve certain emissions requirements and finally, we have performance. So the performance of the exhaust system, it dictates its design to a certain level.

Now obviously different vehicles place different priority on those constraints. You know, certain vehicles will have a very strong emphasis on fitment, for example, or noise reduction, whereas other vehicles, perhaps performance vehicles will make more efforts to achieve performance from a system. But the exhaust system, and in fact those different design requirements mean that an exhaust system is one area of a vehicle where a performance part can make quite a significant difference to the performance of the engine.

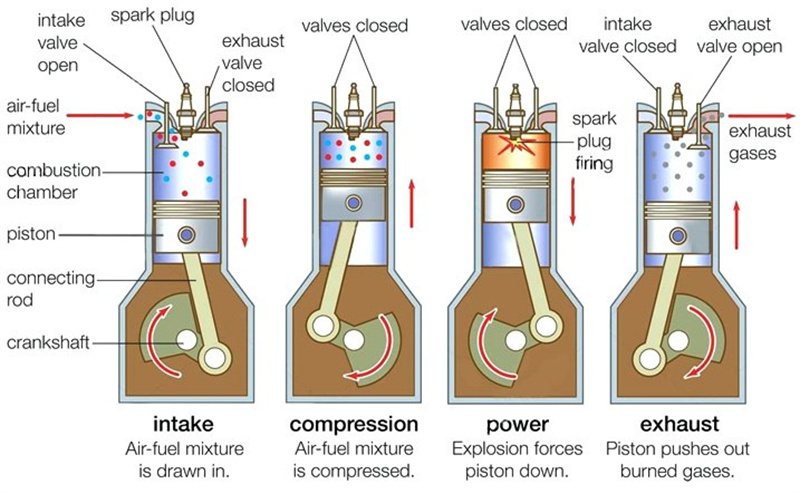

Now we gonna talk about header design and the effect of what is called scavenging, which is the way the exhaust gasses are pulled through the engine, it increases airflow and volumetric efficiency. We will talk about all of that when we discuss the header. But just know that the trade-offs between those designs, affect the design and the performance of an exhaust system.

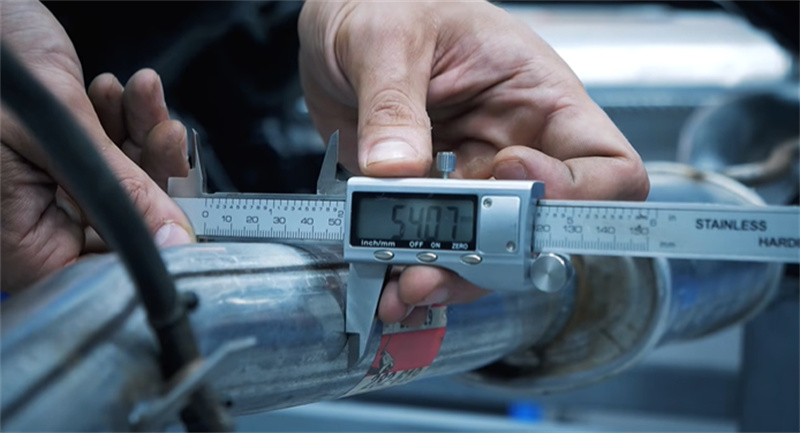

One of the most noticeable things in looking at an exhaust, is the diameter of the pipes. So the diameter of a main exhaust pipe, is determined by the flow of air through the engine at peak revs. So the cubic feet per minute is the measure that is used for this. We measure the amount of gas coming out of this engine, in cubic feet per minute at its peak and then the rest of the exhaust system is sized around that requirement. So a general rule of thumb is that for every horsepower, there is two cubic feet per minute coming out in terms of exhaust gasses.

So the engine of 2001 Mazda MX5 Miata generates 108 brake-horsepower, stock engine, stock 1.6. So this will produce about 220 cubic feet per minute of exhaust gasses and those need to be carried away along the pipe. So this is a classic, you know, your standard size of exhaust pipe on a road vehicle is two and a quarter inches. So if we measure this pipe, let us take a look at here at the diameter of this pipe, we got 55 millimeters which is about two and a quarter inches, so this is just your classic exhaust pipe.

Now on a V8 engine, you would find that you would have, you have obviously got a larger, a larger amount of exhaust gas being brought out, you will probably still find two and a quarter inch pipe on there as a stock fit. But you would find that you got dual exhausts. So one exhaust coming off one side and another exhaust coming off the other bank of cylinders. And those then make their way to the rear of the car so you have effectively got two exhaust systems on a V-shaped engine.

So it can be tempting to think that a bigger exhaust pipe is going to increases the performance of the vehicle. It is going to move the exhaust gasses quicker to the rear of the vehicle. And that is actually not true. So what you find is if you have a pipe which is too big, then the velocity, the speed of exhaust gasses flowing along that pipe, slows down and if you have a pie that is too small, obviously, that restricts the flow. But it is important that there is an optimum size of pipe, it is not just a case of let us throw a big old five inch air conditioning duct at this thing and pump it out the back of the car and put a big old bucket-sized tailpipe on there and it is gonna look really sporty. You might a whacking great tailpipe on the end of a car, nut most likely you have got two, two and a quarter, two and a half inch pipe running and actually along the inside of the vehicle.

And the construction, the actual material that is used for an exhaust system, is generally mild steel. Virtually all stock exhausts are made from mild steel. And you will know that exhaust systems are renowned for rust and corrosion and you look underneath the vehicle, you see a rusty exhaust. Well why is that? It is because exhausts have a particularly tough life. So they operate at high temperature a lot of time, that temperature fluctuates as the exhaust heats up and then cools down.

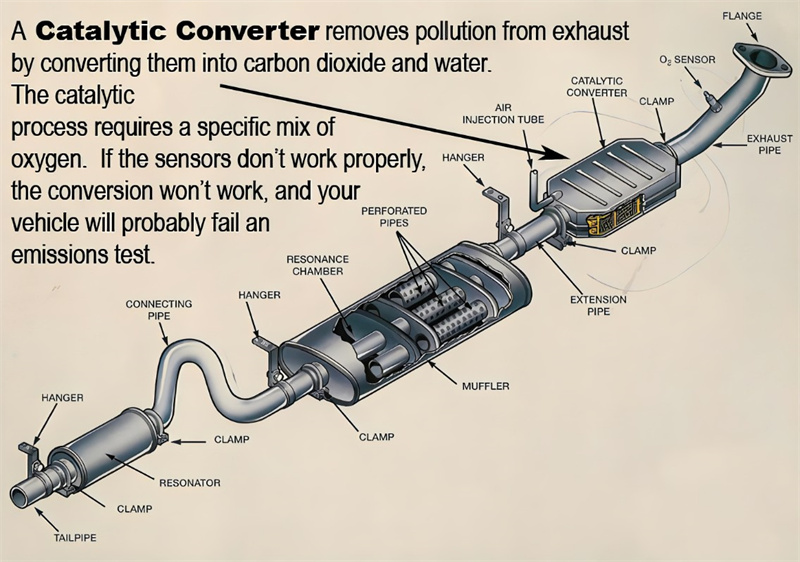

Plus they are filled constantly with these noxious, nasty, corrosive, hot gasses which cause and accelerate corrosion internally. Not only is there hot gasses in there, there is also steam. So steam is a byproduct of the combustion process and when the engine first starts, it generates steam and that steam will build up and pool inside the exhaust system and it will pool particularly inside the mufflers, inside the catalytic converters, until the exhaust gets up to temperature and then obviously that water will then reboil and be taken out of the tailpipe of the vehicle.

But until then, it sits inside these pipes. And if you have a vehicle which travels lots of short journeys, and the exhaust system never gets up to temperature, then it will tend t corrode much more quickly because you got this buildup of water and steam inside the exhaust system. Plus, the exhaust hangs down underneath the vehicle, so it is in contact with any salt on the road and just general water and weather all the time. So exhaust systems will tend to corrode. One way around that is an aftermarket exhaust system which is made from stainless steel.

So here we have two exhaust systems, exactly the same and these are the same age. These came off vehicles the same age. This one is the stock, stainless steel, mild steel exhaust system. Another one is stainless steel and you can see the difference in wear. Even on these pipes here, obviously they are a little gritty, but they are not heavily corroded and pitted and rusted like this one. So stainless steel exhaust , better, will last longer, but they are considerably more expensive.

You find these flexible joints on transverse mounted engines. So when an exhaust fits to a transverse mounted engine, that is an engine that fits sideways. It runs laterally across the vehicle instead of along the length of the vehicle like the vehicle here. So what we have here is a rear-engine rear-wheel drive vehicle with a transverse mounted engine. So you can see inside, the engine runs across the vehicle.

This is much more common in a front-wheel drive vehicle or in an all wheel drive vehicle and the reason they have that flexible joint on the exhaust is that transverse mounted engines will tend to rock more because they are driving the wheels side-to-side and the actual engine in spinning side-to-side as opposed to a longitudinally mounted engine which has less of a tendency to rock.

And if you want to get really fancy on a aftermarket exhaust, you can leave your message to us. We are specialized to auto parts supply chain service since 2004. We supply aftermarket exhaust which not only is gonna last longer. It is completely corrosion resistant. It is also gonna be much lighter than steel exhaust. And it produces a completely different exhaust sound, because of the nature of the material.

So that is a general overview of the exhaust system. It is one of the most important systems in vehicles. It contains the header, the manifold, the EGR system, the catalytic converter, the O2 sensors, and the silencers and mufflers. Hope this article will be helpful for you. See you.

Post time: Oct-18-2022